Keep Pulp And Paper Felts Clean With Our Range Of Felt Cleaning And Conditioning Chemicals

Product Details:

| Place of Origin: | SHANDONG PROVINCE, CHINA |

| Brand Name: | JHDA |

| Certification: | ISO9001;ISO14001 |

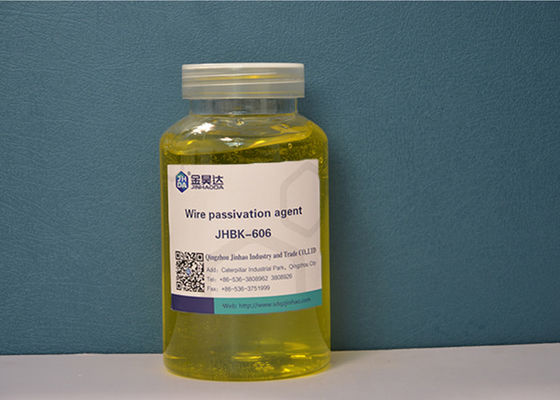

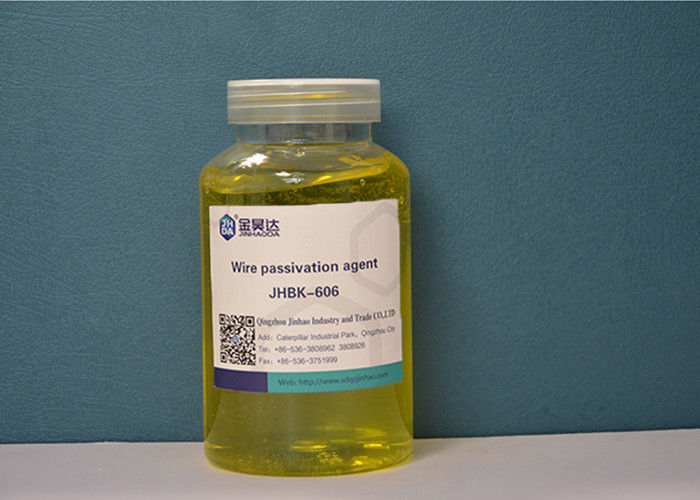

| Model Number: | JHBK-606 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1MT |

|---|---|

| Price: | USD680-730/MT |

| Packaging Details: | 200L drums, 1000L IBC drums or Flexitank bag |

| Delivery Time: | 5-8 working days |

| Payment Terms: | L/C, D/P, T/T, Western Union |

| Supply Ability: | 6000TONS/M |

|

Detail Information |

|||

| Appearance: | Colorless To Light Yellow Liquid | Application: | To Optimize Wire Conditioning Performance |

|---|---|---|---|

| Keywords: | Cleaner For Paper-making Felt | Grade: | Industrial Grade |

| Color: | Colorless Or Light Yellow Liquid | PackAge: | Standard Export Seaworthy Packaging |

| Name: | JHBK-606 Wire Conditioning/passivation Agent | PH: | 10-14 |

| Highlight: | Felt And Wire Passivation Agent,Tissue Mills Passivation Agent,JHBK-606 Cleaning Agents |

||

Product Description

Keep pulp and paper felts clean with our range of felt cleaning and conditioning chemicals

1.Brief Introduction

JHBK-606 is a kind of polymer made from advanced surfactant,penetrating agent,emulsion,anstatic agent,auxiliary detergents and etc.By using it,he stickies of dryer screen can be better penetrated and cleaned.It can be used during or after equipment operation.The permeability of dryer screen can be improved.The cleaning dryer parts operation can prolong the working time of dryer screen.The paper broken situation resulted from sticky dirt will be avoided greatly.

With passivation a thin chemical layer is created on the formic fabric or on the press felt.

This chemical layer avoids the deposits if substances on the clothing surface.

The passivation is the best treatment when deposits are on the surface and not into the surface.

2.Main Spec:

Appearance:colorless to light yellow liquid

Solid content:25%±1%

PH:10-14

Viscosity(25℃):≤50mpa.s

Solubility:easily soluble in cold water

3.Dosage&Application tips:

3.1 Dosage: 0.1kg to 0.3 kg for each square meters of dryer screen.

3.2 To dilute it with water of 10 times to 50 times.To spray onto the dryer screen when the equipment is in crawling speed.After around 20 minutes operation, the dryer screen should be cleaned thoroughly.It can also be cleaned continuously during the operation process.

4.Notes:

To avoid contact with eyes.If , please rinse out immediately.

5.Package,Storage&Shelf Life Time

The package can be 200 Liters or 1000 Liters drum. It should be stored in cold place.The shelf life time is 12 months.

5.Main Specifications:

| Appearance |

colorless or light yellow liquid |

| Viscosity(25 ℃) | ≤30mpa.s |

|

PH value |

10-14 |

|

Solubility |

easily soluble in cold water |

![]()

![]()